3D titanium printing is a technology that uses titanium powder to create a three-dimensional object from a digital file. The titanium powder is melted and then forced under high pressure and temperature into a mold, where it becomes the shape of the object. The object is then heated until it solidifies, at which point it is removed from the mold and can be used as the base for a new object.

Prints Titanium 3D Parts

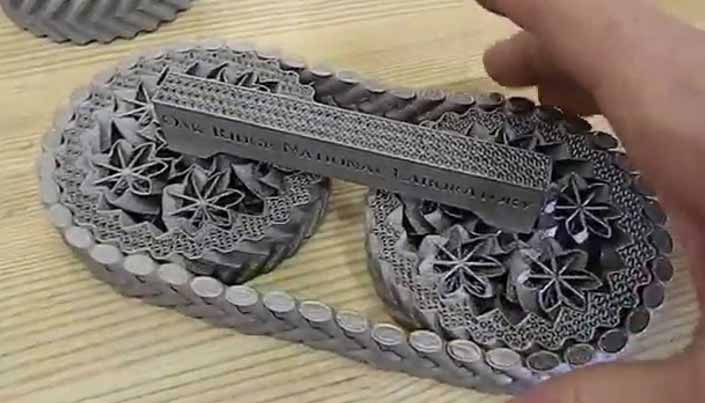

When the laser hits the titanium powder, the liquid titanium takes shape, forming the 3D part. This process is entirely inside the printer, requiring only that a user upload a 3D file. Once the file is imported, the printer will start working. The printing process can take anywhere from 30 minutes to several days, but it’s important to remember that the 3D printing process can be quite time-consuming.

3D Titanium Printing Technology

The advantages of 3D titanium printing are numerous, but perhaps the greatest is the fact that it is one of the strongest metals. It allows designers to explore new design constraints and produce end-use products in a faster timeframe. The technology allows for small production runs of identical objects, allowing for customization without extra cost. The advantages of this process are obvious: it offers an unprecedented amount of design flexibility and allows for the rapid prototyping of prototypes and other objects.

Titanium is an Affordable Metal

Apart from its strength, 3D titanium printing can also save money, which makes it a viable alternative for the aerospace industry. Its low cost makes it affordable for manufacturers, and it is used by many different industries. There are several benefits of 3D titanium, and one of the biggest is that it is one of the most expensive metals in the world. It also allows for the reduction in buy-to-fly ratio, which is the ratio of raw material to finished weight, check this site out.

Limitations of 3D Titanium Printing

There are a few limitations to 3D titanium printing, but the advantages are worth it for the industry. First, titanium is a strong metal, but it is also brittle. In addition, it can be expensive to manufacture. This is the reason why titanium is so popular for aircraft manufacturing. Its strength and durability make it a great option for aerospace applications. The only disadvantage is the lack of scalability.

There are a few benefits of this material. The best feature of titanium 3D printing is its low waste. Compared to conventional manufacturing methods, it produces fewer waste materials. This is the main advantage of the material. In contrast to conventional manufacturing methods, titanium 3D printers generate a lot of waste. They generate a lot of support structures and materials. Therefore, they are cheaper to make than conventional components.

Conclusion:

Although 3D titanium printing is not for home users, it is an essential element of the medical industry. The benefits of titanium additive manufacturing include scalability and precision. By using a powder bed process, a part of titanium is made by melting a thin layer of metal wire. Ultimately, the result is a solid part that meets the specifications of the client. The printer also eliminates the need to use metal-based adhesives.